SEMICON China connects the global microelectronics supply chain with one of the world’s most dynamic semiconductor markets. It offers a large exhibition floor, technical conferences, and business programs for device makers, foundries, and their equipment and materials partners.

Slide 1

Slide 2

Remanufactured Semiconductor Equipment

We specialize in remanufacturing the leading semiconductor etch and deposition systems.

Slide 3

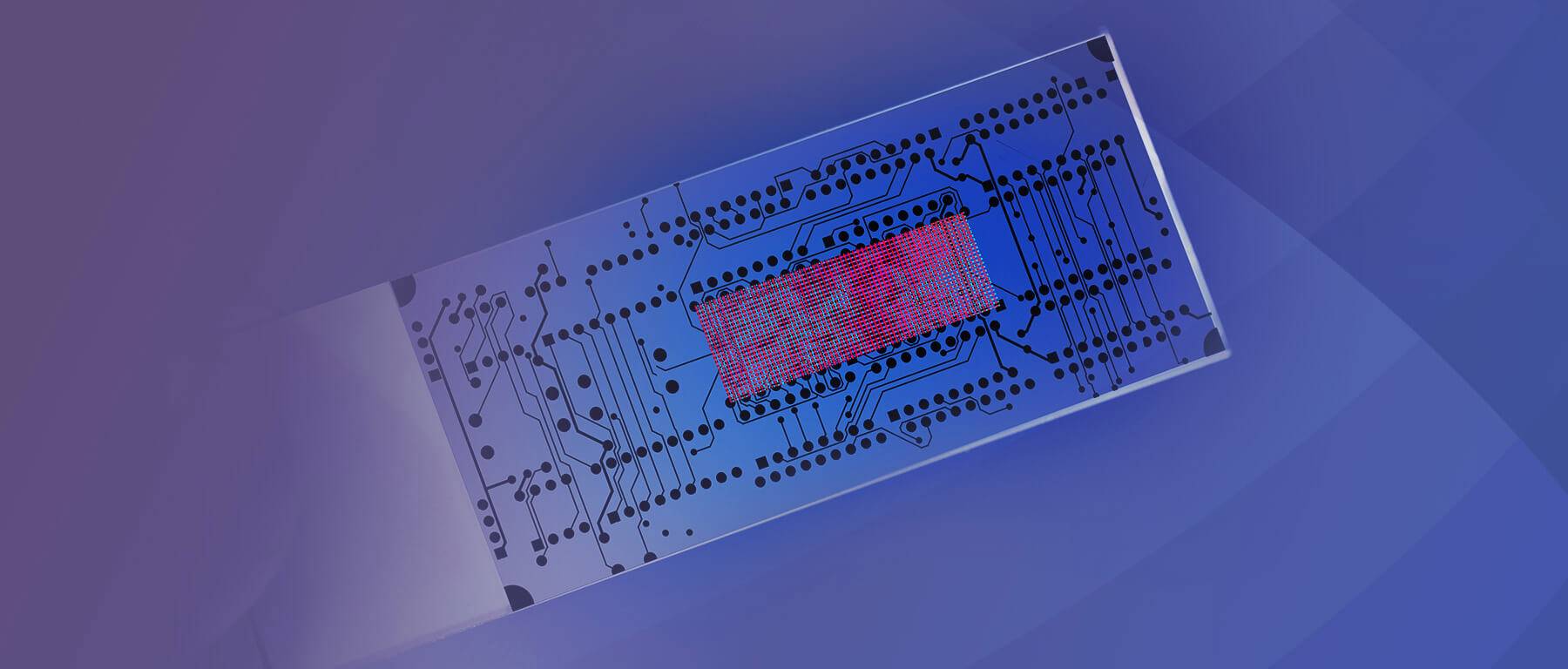

MEMS Equipment for All Needs

From R&D to high volume manufacturing, our MEMS equipment meets your requirements.

Slide 4

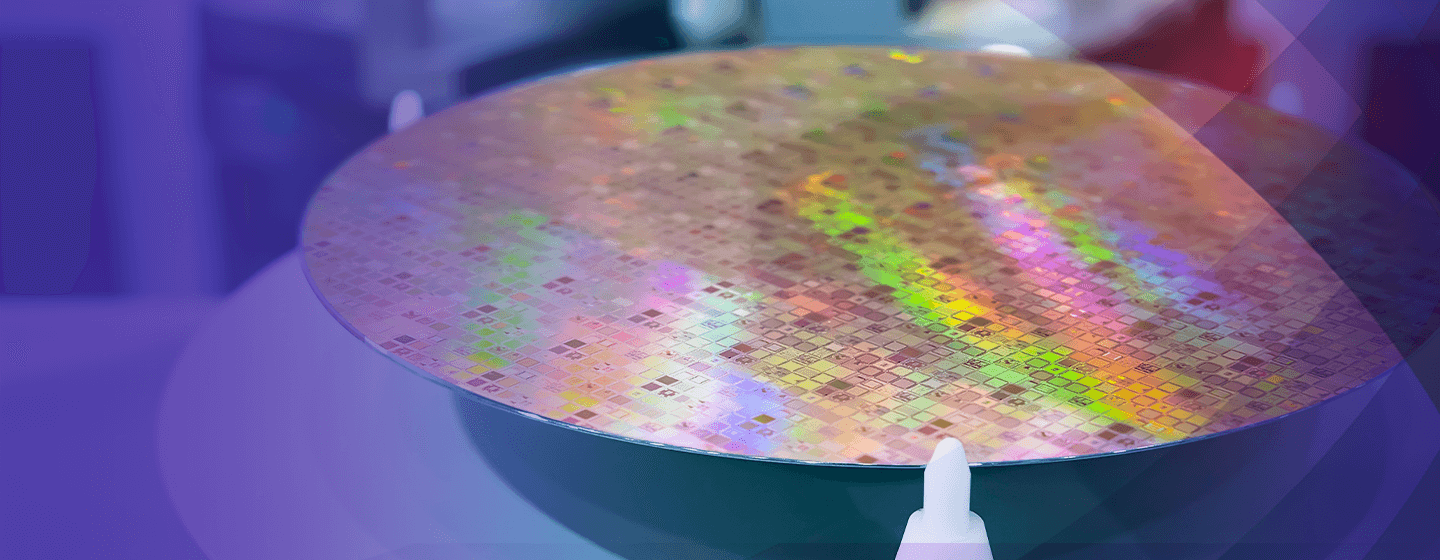

Yield and Cost Drive MEMS’ Move to Single-Wafer Processing

The case for single-wafer tools that can deposit or etch thinner films and meet more aggressive targets for process uniformity with high yield and repeatability is growing.